An entirely biodegradable sneaker concept using soil safe materials and nontoxic glue

Midsole and upper made entirely from reused cotton fabric scraps with a sole cast from bioplastic

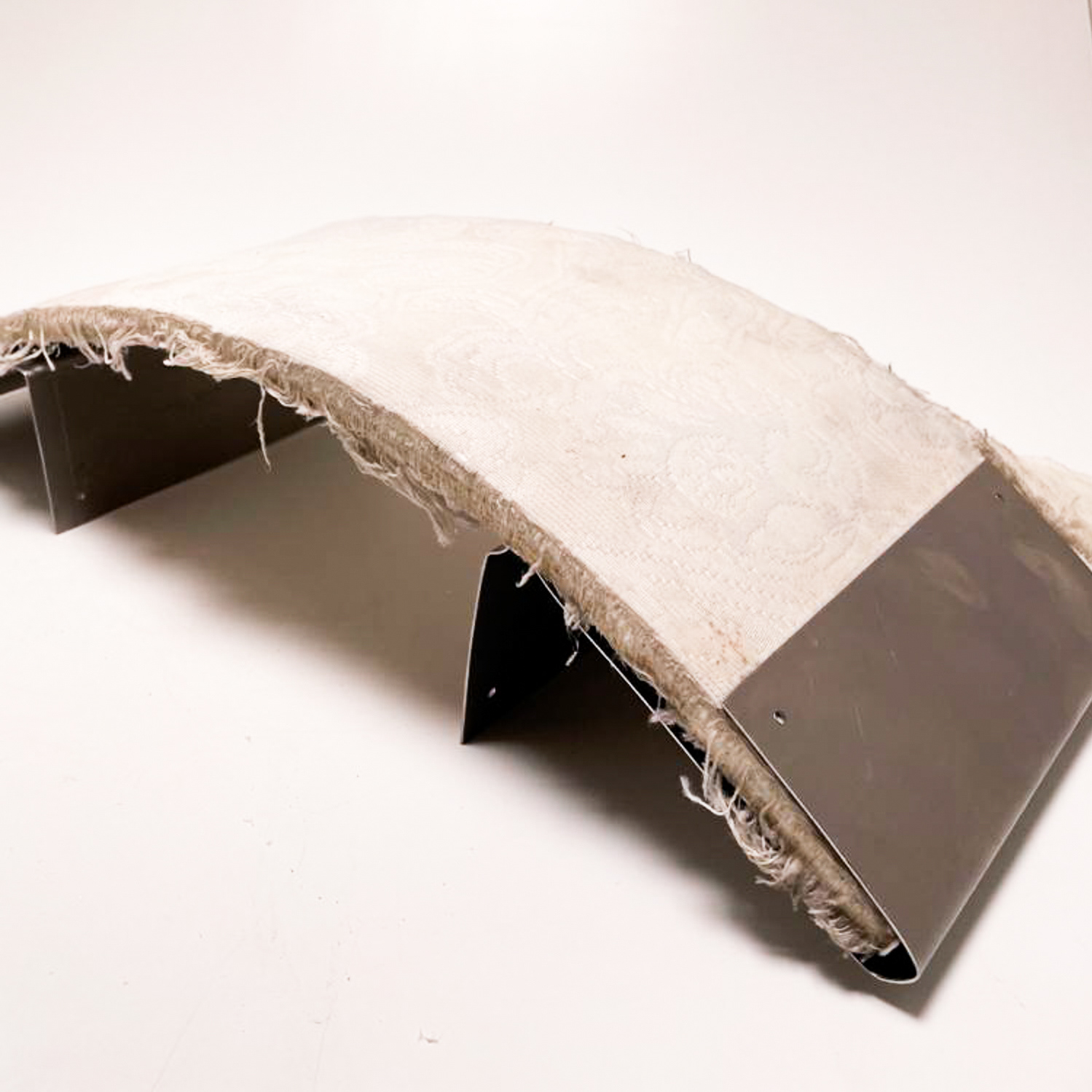

Research began with exploring the possibilities of forming scraps of cotton and linen fabric with a formaldehyde free wood glue.

Using found materials to function as molds to form the fabric demonstrated the variety of shapes the material could achieve.

The more layers of fabric fused together in the molds created a stronger material, enough to withstand human weight in figure 4.

Depending on application context, the material could replace flexible rubber, plaster gauze, or interfacing.

This discovery prompted the idea to make a shoe to demonstrate the intelligence of the material.

1

2

3

4

5

6

Outsole

Midsole

Outsole: Sculpted positive mold of clay for vacuum forming before pouring bioplastic recipe

Midsole: Layered fabric formed around shoe last and mold before cut on bandsaw

Upper: Constructed with scraps using material technique for a supportive heel and toe support.

= zero non-compostable hardware

or materials

After conducting extensive bioplastic binding with salvaged wood shavings from a carpentry shop, using the "v12" recipe was found to have the perfect ratio of:

- sodium alginate - listerine - glycerin - wood shavings - rice glue -

to bind/permeate a layer of cheese cloth and adhere to the midsole.